Agile Development

High Quality Production

Unique Features

Technology Leadership

Based on years of extensive development work, AST is using the Surface Mounted Fluidics technology as first in class for its unique space products.

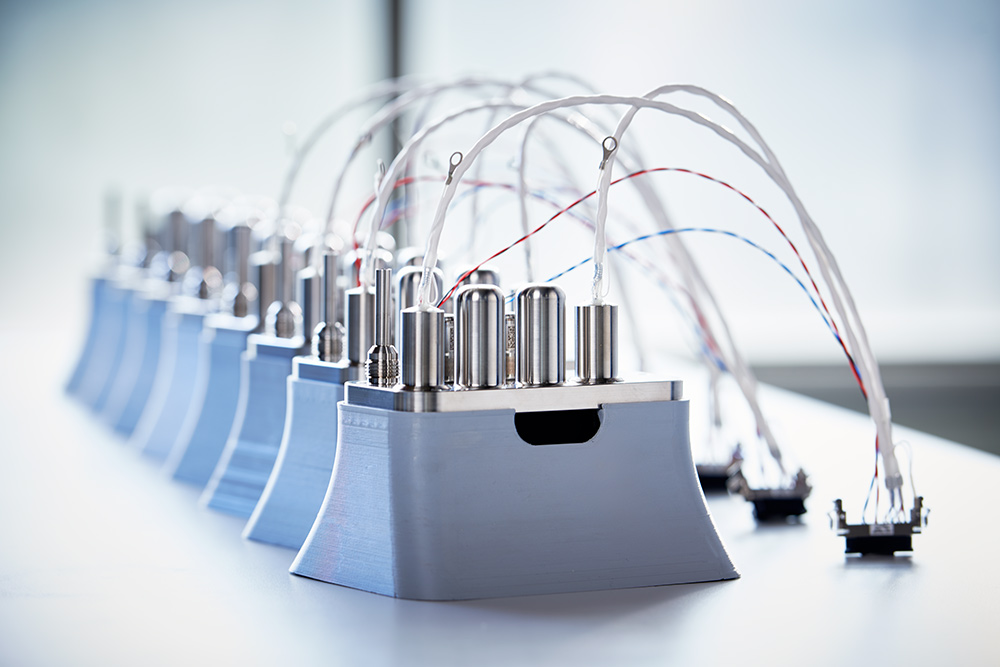

Serial Production of Space Equipment

AST’s products are designed to allow for high-volume production at low production cost per unit – always keeping product quality at spaceflight level.

Products Made in Europe

With the production based in Germany and key-partners located closeby, AST is a true European provider of fluidic spacecraft solutions worldwide.

Cost Effective Serial Production

Our design for serial production is unique in space business and yields significant cost savings at larger quantities as required by LEO megaconstellations.

Welcome to AST

The Perfect Solution for Space Applications

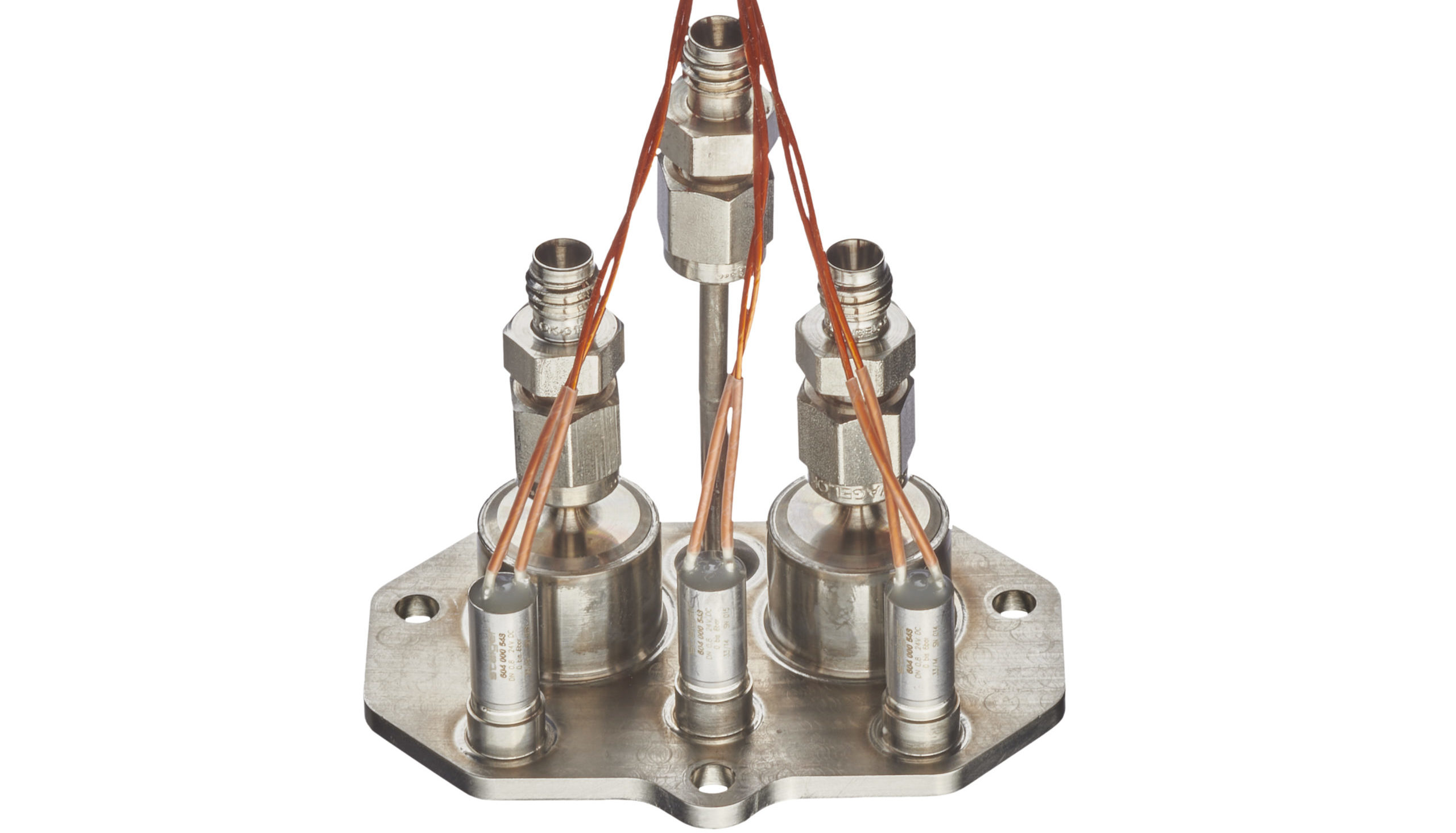

AST is leader in high performant and miniaturized flow control components and units for space applications. Our devices use fluid SMD technology to reduce system size and mass and to allow series production. Key feature of fluid SMD is the significant reduced number of welds and a quality optimized manufacturing process. All remaining welding joints are done in fully automized electron beam welding machines, providing a maximum of quality at a minimum of cost.

High Quality Products

AST's products comply with highest quality standards as for classical space applications like in ESA / NASA missions.

Reliable Components

All components in AST's products have undergone fierce design qualification and are checked for compliance to high quality standards before integration.

AST's Mindset

The Mission

Our longterm mission is to develop products based on technologies that allow large scale serial production of space components at high quality level. With increasing number of units and streamlined processes, the cost of components and devices will be lowered by at least one order of magnitude. Fast development cycles and component spin-in from commercial application are key to keep the pace of NewSpace projects.

Number of Units built

Number of Units in Orbit

Accumulated Time in Orbit

AST Products

Our Product's Key Features

● Unites many functions in a single, compact unit

- less parts on spacecraft

- less AIT cost and time on spacecraft level

- lower mass

- lower accommodated volume

- precision pressure reading

- precision massflow control

- precision thrust control

● customer-specific operation points

- output pressures and flatness

- flow rates

● optional design features

- screwed fluidic connections

- welded fluidic connections

- Fill and Drain Valve

- fixed or variable massflow control

- single or dual output line

- established, scalable, high-volume production line (>600 units manufactured)

- constant unit quality

- cost-effective unit prices

- high production reliability

AST Products

AST's Space Propulsion Fluidics - Main Functions

- high pressure

- low pressure

- fixed outlet pressure setpoint

- variable outlet pressure setpoint

- fixed, controlled propellant massflow

- variable, controlled massflow

- propellant filling, draining and venting

- propellant gauging

- Xenon

- Argon

- Krypton

- Nitrogen

Our Products

What We Offer

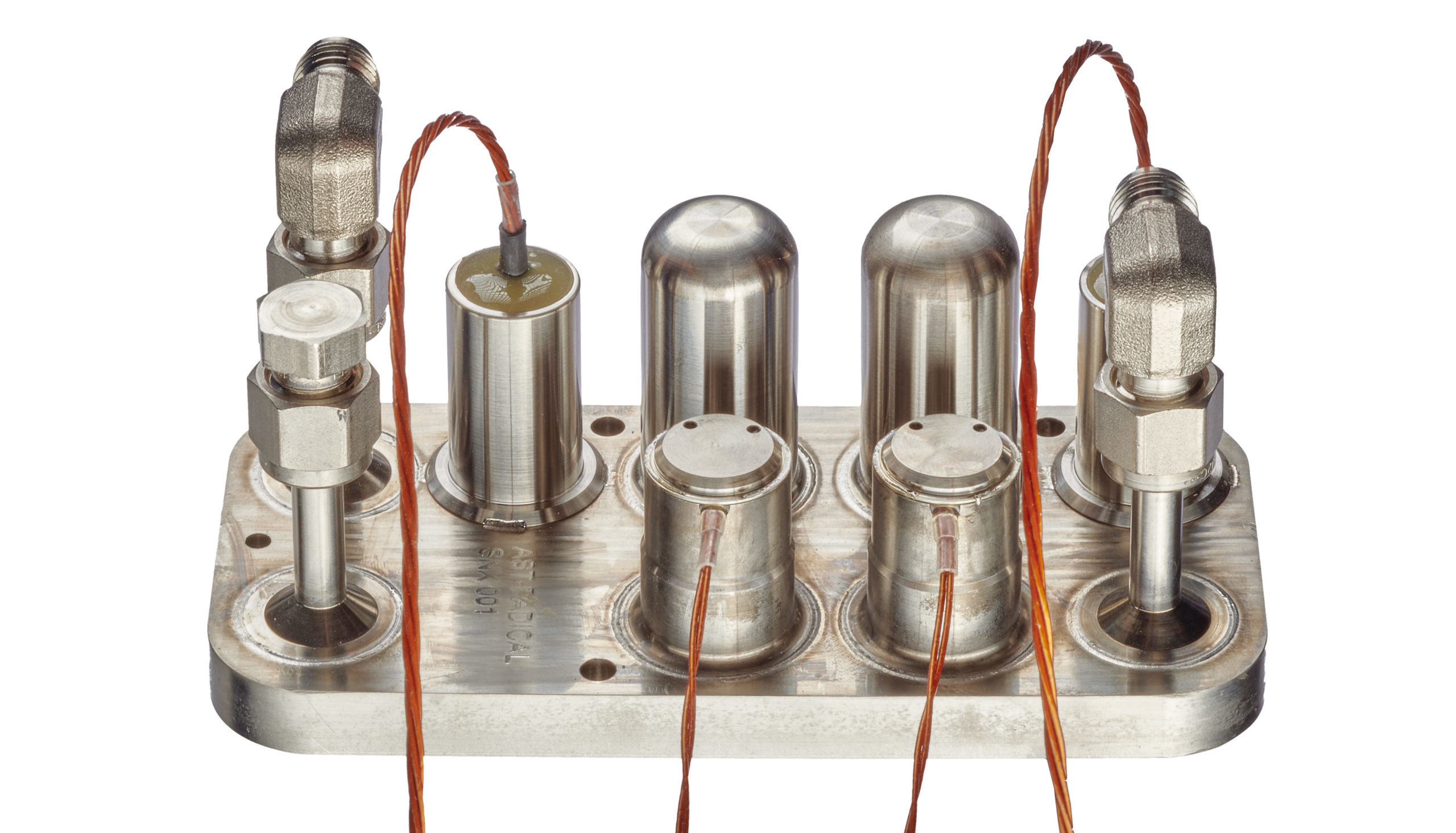

High Pressure Flow Control Units

The AST high-pressure flow controller reduces high inlet pressures and provides correct massflows of propellant. This is best suited for a single-thruster propulsion system.

Low Pressure Flow Control Units

FCUs are used to adjust the propellant gas flow to an electric thruster over a wide mass-flow range and very dynamically. This solution allows for highest in-orbit operational flexibility.

Electronic Pressure Regulator

The EPR reduces high-pressure input to selected low-pressure output levels. It provides operational flexibility e.g. when using cold-gas thrusters in electric propulsion systems.

Cold Gas Thrusters

The AST Cold Gas Thruster is a minuature thrust device with extensive ground testing and has flight heritage. The thrust level is about 50mN depending on media and pressures.

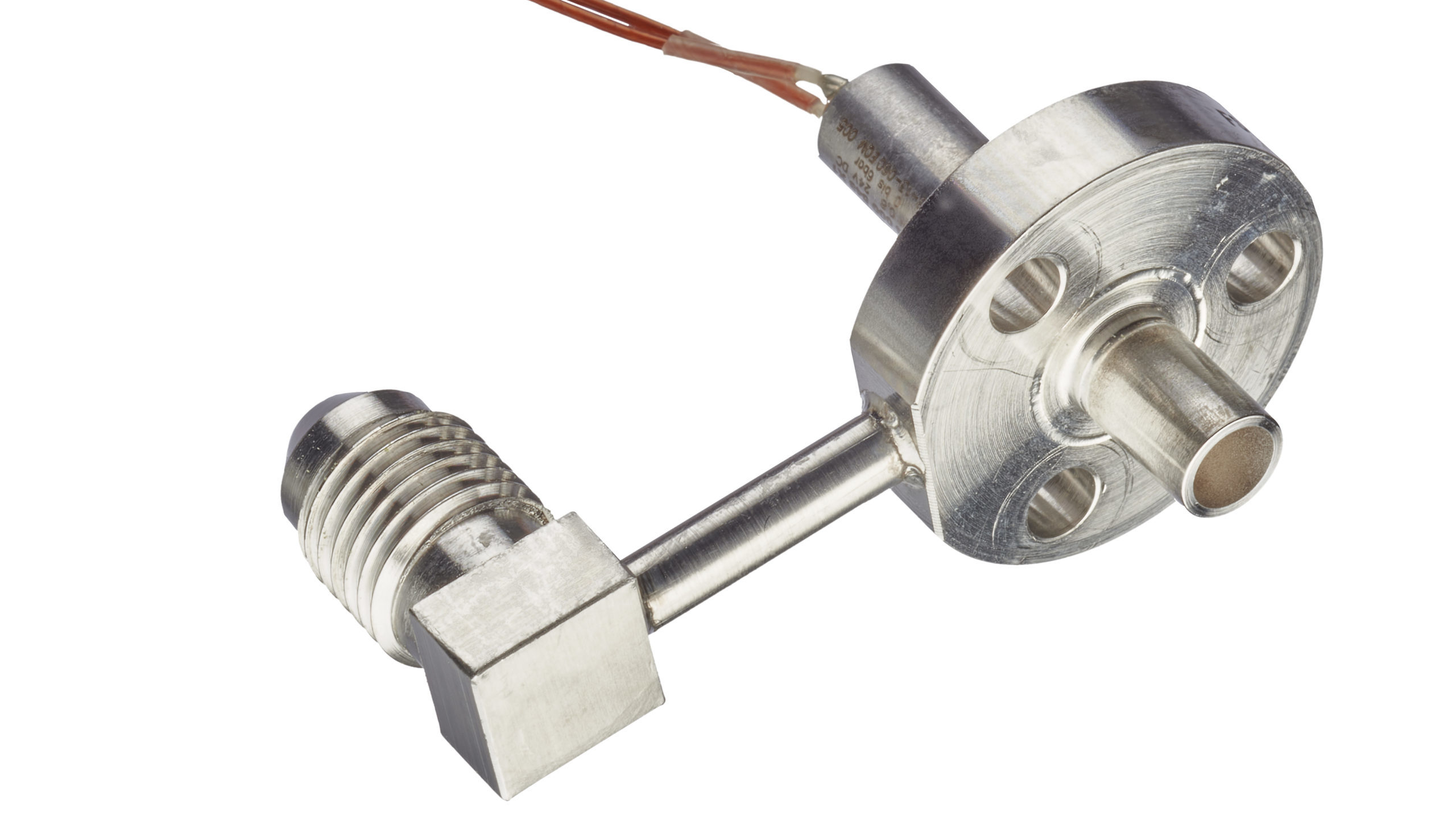

Fill- and Drain-Valve

AST has developed a fill and drain valve that makes a perfect fit onto the Flow

Path Board of its pressure regulator (EPR) and high-pressure flow control unit.

Isolation Valve

AST's miniaturized low pressure valves can be used in complex fluidic systems as stand-alone valves. They have demonstrated a total of 1.1 billion (10^9 ) operational cycles.

Learn More about Our Production and Development Capabilities

AST’s product development team is constantly seeking for new features, improved performances and higher production yield in its existing products as well as for new ones. With its core activity in fluidic components and system development for space applications, the development engineers at AST also create unique test equipment for qualification and serial production test purposes.

AST’s development team is always eager to find the best soltution for customer’s needs.

Contact Us for Enquiries and Questions

For further information about our products and capabilities please get in contact with us.