Production Capabilities

High Performance Through High Precision and Quality

Production Capabilities

Production Capabilities

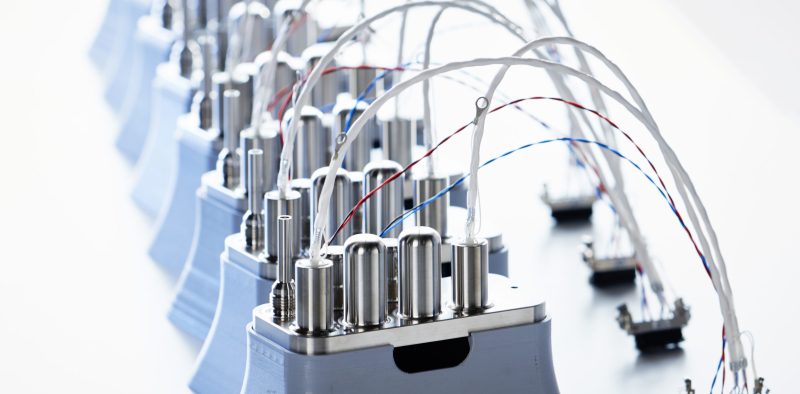

Mastering key processes and technologies are the key to success in developing and manufacturing miniaturized fluid control component for space applications.

AST has developed production processes that allow for high quality and high quantity production of series products. These processes are applied every day on multiple products and improved continuously in collaboration with our customers.

The site of AST is located in Osterholz-Scharmbeck near Bremen (Germany) and offers 5400 m2 offices, labs and production area. Centrepiece of the production is the Clean Room (ISO 8, 175 m2).

Several production processes are performed in-house – where economically useful (and quality requirements allow for) AST works with external partners in Germany and Europe.

Production Capabilities

AST’s Production Facilities, Processes and Technologies

- Electron-beam welding

- Laser Welding

- Clean Room

- Climate Chamber

- Thermal Vacuum Chamber

- Precision Cleaning

- Space certified Soldering

- Space certified Potting

- Curing/Drying Oven

- Leakage Test

- Hydraulic High-Pressure Test

- High Pressure Gas Pulse Test

- Microsection Grinding and Polishing

- Electronics and Unit Tester

- Incoming Inspection

- Milling station

- Turning Station

Production Capabilities

Series Production at AST