Products

Our Products

What We Offer

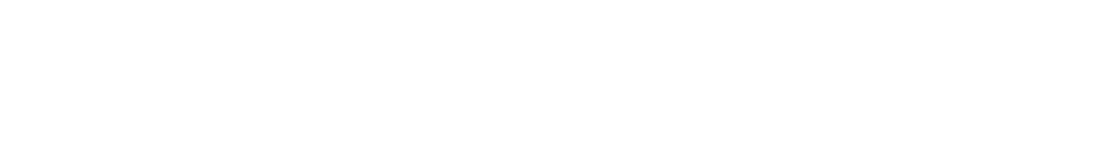

High Pressure Flow Control Unit

The AST high-pressure flow controller provides correct massflows of propellant to an electric propulsion thruster. For this, it transforms the propellant provided by a propellant tank with variable input pressures (e.g 150bar down to 2bar) to a constant flow of propellant to two outlet ports, which are then connected to the thruster and its neutralizer cathode individually. The challenge of the flow-control function is to provide a very accurate, stable and known massflow to assure operation of the thruster in the desired operation point. The AST design combined all required functions in a single unit, which provides significant advantages on subsystem is therefore a “RADICAL” improvement. With a unit mass below 1 kg and the footprint of a cell phone the RADICAL flow controller fits into any system budget and consumes almost no space.

With its low-complexity design it is streamlined for series production to reach the cost target of modern LEO constellations. At the same time it allows for adaptations to customer specific needs in terms of accommodation and external interfaces without changing the core functions and performance of the high-pressure flow controller.

The baseline design is optimized for Xenon. A Krypton version is under development. All high pressure flow controllers are designed for a inlet pressure of 300 bar. More than 350 units for Xenon operation are currently operated in orbit.

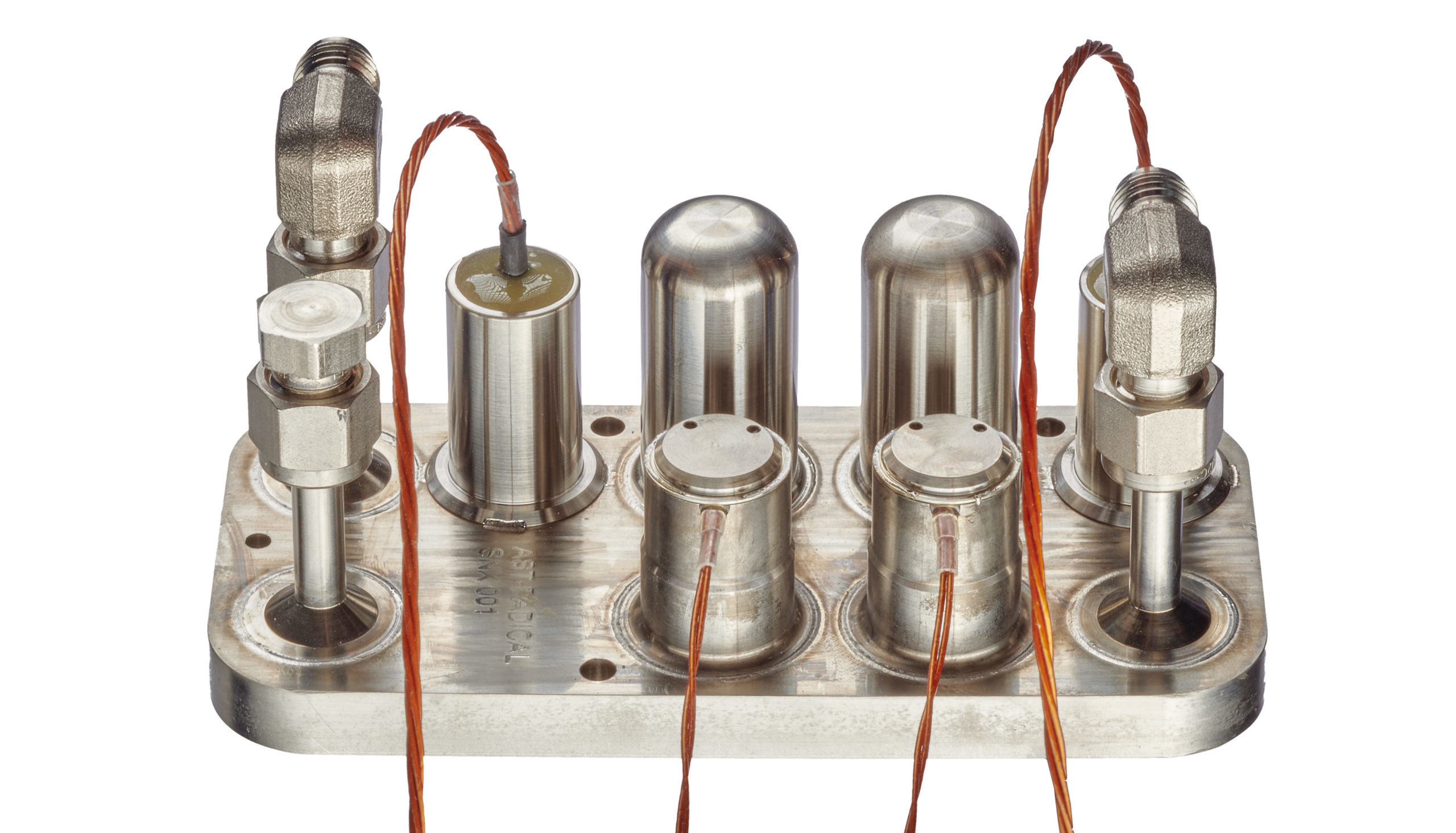

Low Pressure Flow Control Units

Flow Control Units (FCU) are used to adjust the xenon gas flow to an electric

propulsion system using ion engines or plasma thrusters.

AST offers a family of miniaturized flow control units (μFCU) with different flow

capabilities ranging from 0.1 mg/s F.S. for micro thruster up to 10 mg/s F.S. for

high power HETs. The flow range is determined by internal passive flow resistors

which allows an easy adaption to individual specifications.

The standard miniaturized flow control unit design provides two independently

controlled flow channels. The control can be done in open loop or closed loop to a

thruster parameter like the anode current.

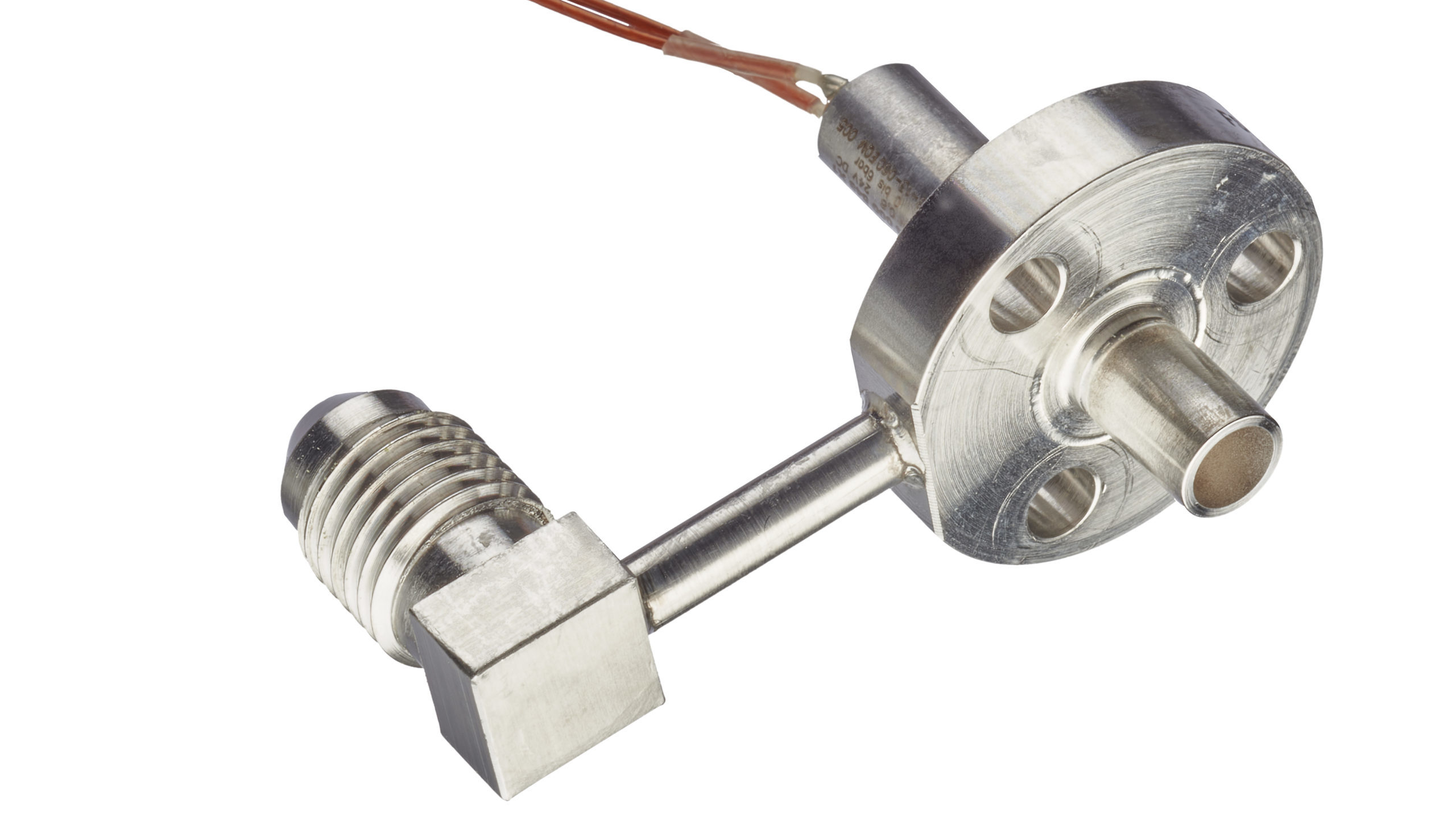

Cold Gas Thruster

The AST cold gas thruster has been developed for the FORMOSAT 5 mission. It

provides a nominal thrust of 42mN at 69s specific impulse (@1.5 bar nitrogen). A

large range of linear control by the inlet pressure has been demonstrated from

20mN to 150 mN with the same thruster.

The Cold Gas Thruster has been qualified in 2014 and is in orbit since 24th of

August 2017. Further developments have been finalized in 2021 and serial

production for a wide range of use-cases has started.

A thruster configuration for operation with Xenon is currently under delta-

development.

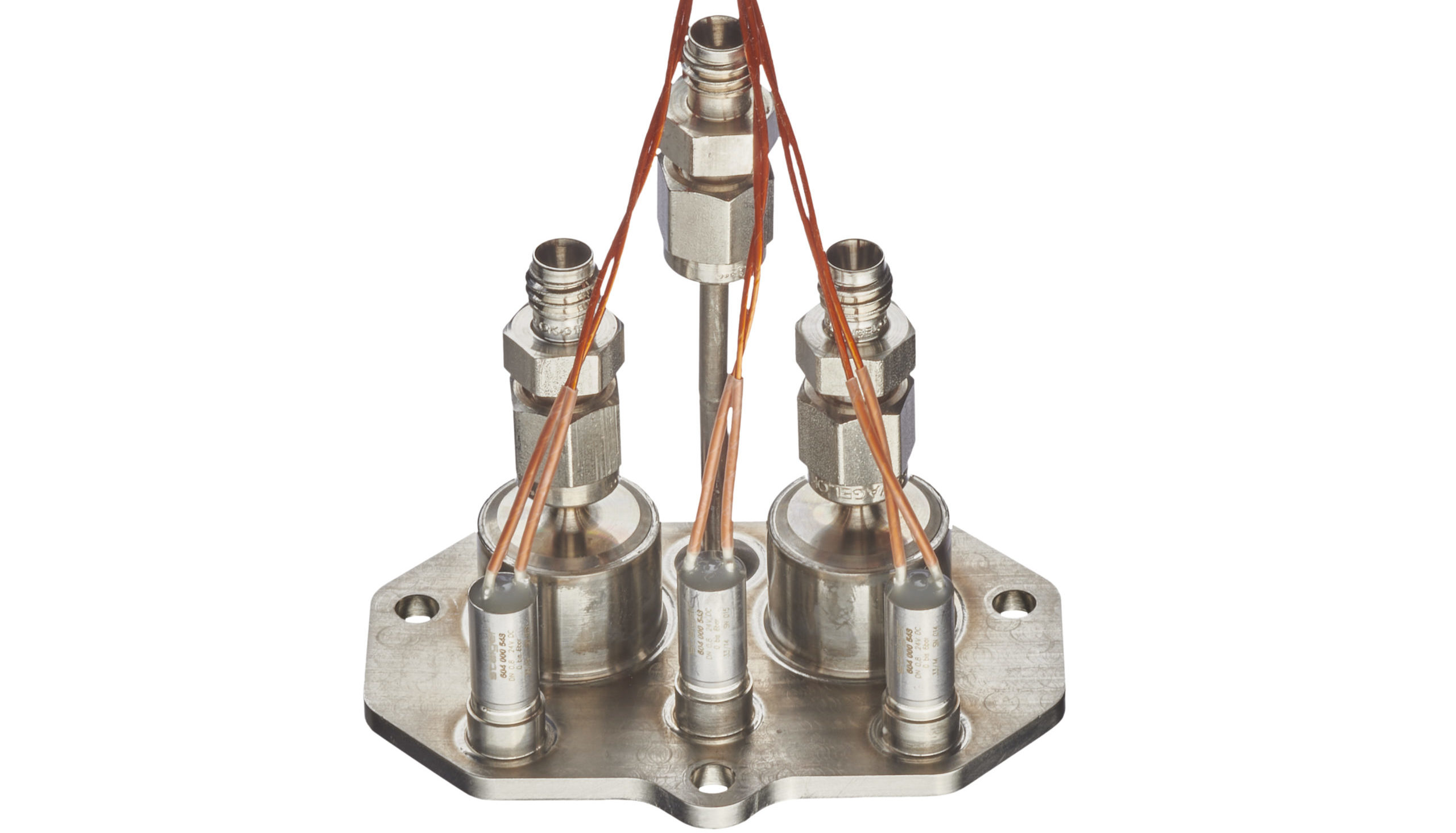

Electric Pressure Regulator

The Electric Pressure Regulator (EPR) is qualified for operation with Xenon up to 150 bar. It weighs about 800 grams (w/o electronics) for a full functional

fluid block with triple barrier against propellant loss.

Target application are electric propulsion systems with xenon flow rates of up to

400 mg/s to supply the EP system and xenon cold gas thrusters.

With all components beeing high-pressure proof, operation up to 310 bar (e.g. for Krypton) can be performed. With this, AST's EPR design is ready for all today’s and future EP systems.

Fill- and Drain-Valve & Ground Half Coupling

AST has developed a fill and drain valve that makes a perfect fit onto the Flow Path Board of its pressure regulator and high-pressure flow controller. It allows for high pressure filling of the fluidic system and with its triple barrier provides a highly reliable protection against external leakage. An inlet filter increases system robustness against particulate contamination and therefore increases overall reliability. A stand-alone unit can also be provided on demand

Fill- and Drain-Valve & Ground Half Coupling

Together with the fill and drain valve, AST has developed a matching ground half coupling that is

used during ground operations to fill the fluidic system with propellant. The manual valve has

been optimized to allow for multiple safe operations with high leak-tightness and robustness

against handling errors.

Isolation Valve

AST's miniaturized low pressure valves have been developed for an outstanding high actuation

lifetime. A total of 1.1 billion (10^9 ) cycles have been demonstrated.

The stand-alone valve can be used in distributed flow control systems to activate / deactivate

fluidic lines in ON/OFF or pulsed mode operation.